Description

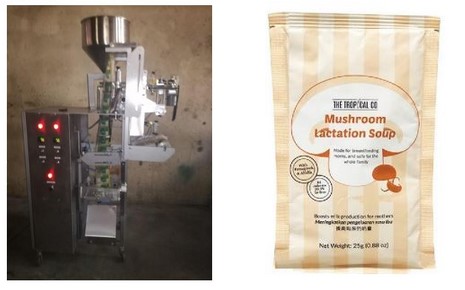

MODEL: PRO-PAK II FORM FILL AND SEAL SACHET MACHINE

Operation Parameter

- Product: Powder Spice

- Target weight: 50g & 100g

- Packing speed: 30-50BPM

- Bag shape: Standard pillow bag

Machine description

- vertical form fill sealing packing machine

- Auger dosing head.

1. FFS BAGGER PRO ||- Specifications & Technicals

PRO-PAK II – Form Fill and Seal The PRO-PAK II Series Form, Fill, and Seal machines are the ideal equipment for the forming and filling and sealing of single-use plastic pouch packages such as soups, spices, sauces etc. PRO-PAK II systems are also capable of filling powdered products with an optional auger filling module examples include chili powder, spices, and powdered drink mixes. Each system is constructed of stainless steel with all contact parts made stainless steel. Utilizing a simple manual control and adjustable setting system which ensures that each of the PRO-PAK II Systems is easy to set up and can maintain trouble-free operation at speeds up to 50 PPM. Filling ranges of 8-1000mL within packet lengths of 30-300mm and widths 30-200 are within the capabilities of the PRO-PAK II Series Form, Fill and Seal machines. These units require a 220 volt supply and a minimum of 8 cfm air supply. They are roughly 1400mm wide x 2200mm high and 900 mm in depth, which makes them easy to place. The liquid filler units make use of a piston filler system which is totally discharged volume adjustable and an “eye” mark printer can be incorporated as an optional extra. The packaging process begins when the heat sealable film is pulled into the machine and positioned to form a pouch. Once in position, the film is sealed on the left side and bottom to form the lower part of the packet. This open packet is moved to the filling station where a metered amount of your product is dispensed. Each packet then advances to the final sealing area for top end sealing. Any date/lot code embossing is also completed during the top sealing operation. Once the packet is completely sealed they receive their “Easy-Rip” open tab and final separation cut. Each PRO-PAK II system delivers this per”form” ance, fill and seal process continues through the work shift making it a solid addition to any sample packet packaging line.

Features

- Auger dosing system

- Side heated sealing module adjustable from 30 MM to 300MM

- Top and bottom horizontal heated sealing modules adjustable from 10 MM to 200MM

- Solid heavy steel construction for years of trouble-free service

SPECIFICATIONS & TECHNICAL

height: +/- 2500 mm Max

length: 1400 mm

Depth: 900 mm

Weight: 500 kg

Electrical: 220 VAC, 50 Hz

Fill Size: 8-1000g

Options

- Horizontal sealing line dye (Zigzag or Horizontal Line)

- Ribbon date coder

- FFS Bulk feed auger from ground level

- Extended hoppers and float kits

- Three seals change part set

- Easy tear notch

- Powder or granule filling module or liquid ( specify )