Description

POWDER PACKAGING MACHINES

Video Player

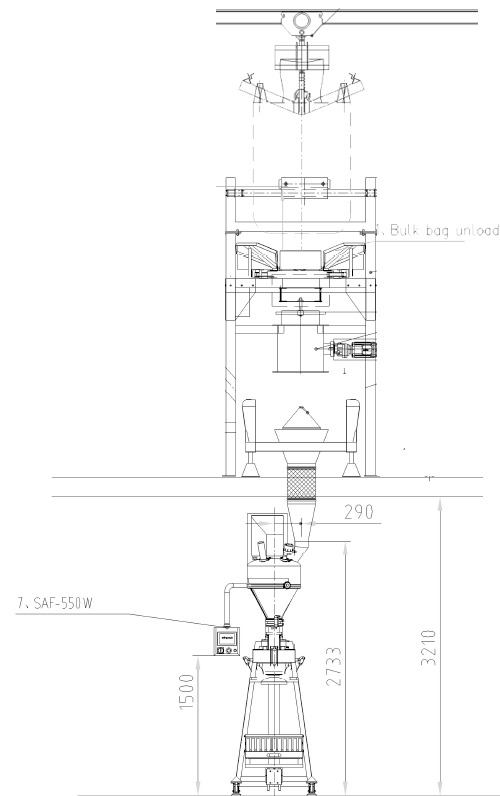

00:00

00:00

SPC: 1kg to 30kg powder filling

QUOTATION

| No | Item | Model No | QTY | Unit Price | Total | ||

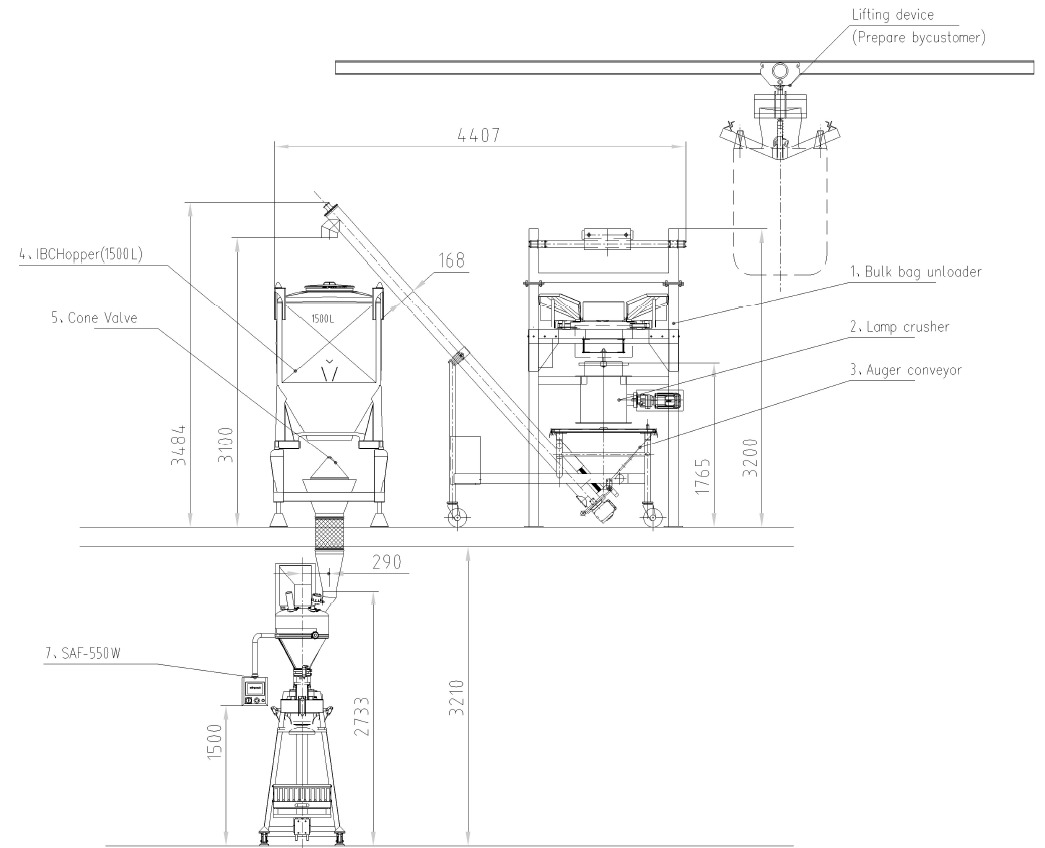

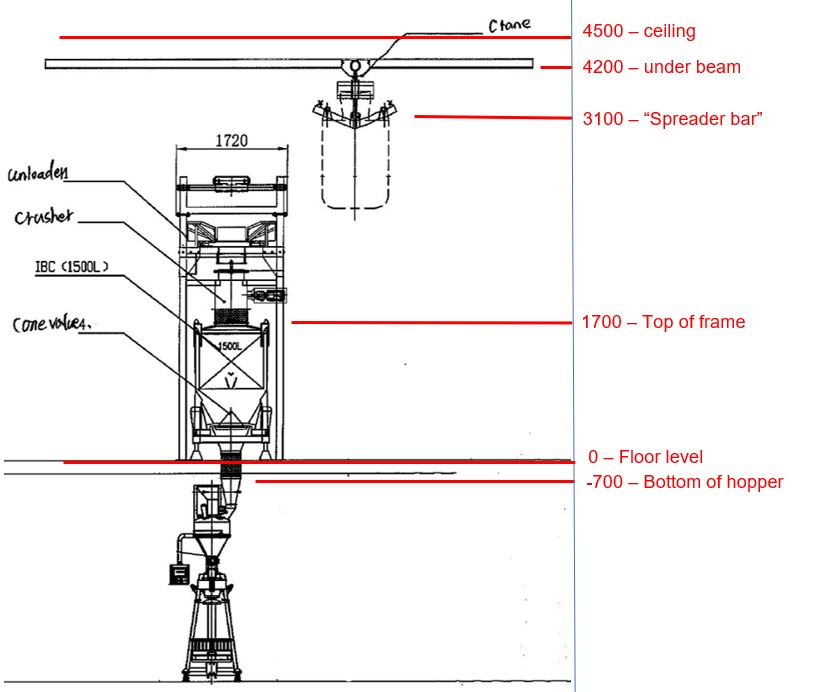

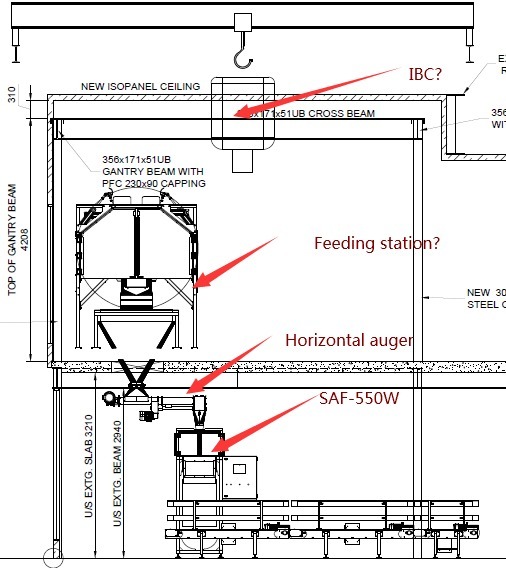

| 1 | Hoist Unloader | Without Hoist | 1 | ||||

| With Machine | 1-1.Bag Clamp | 1 | |||||

| 1-2.Pneumatics Extrusion | 1 | ||||||

| 1-3.Supporting Frame | 1 | ||||||

| 1-4.Discharging Connector | SUS304 | 1 | |||||

| 1-5.Control | 1 | ||||||

| Optional | 1-6.Bag Squeeze | 2 | |||||

| 1-7.Dust Collection for the hoist unloader and auger | DC 2.2A | 1 | |||||

| 2 | Lamp crusher | 1 | |||||

| 3 | Horizontal Auger Conveyor | EAC-168-500 | 1 | ||||

| With machine | Hopper | 50L Hopper | 1 | ||||

| 4 | Weighing Auger Filling Machine | INAF-550W | 1 | ||||

| With machine | 4-1.Auger Tooling | #12 For Dosing range 1kg | 1 | ||||

| 4-2.Horizontal (Half Hinged Open Hopper) | 80L | 1 | |||||

| 4-3.Bag Clamp with load cell | For bag: W400-600mm | 1 | |||||

| Optional

|

4-4.Auger Tooling | #13 For filling 2kg | 1 | ||||

| 4-5.Auger Tooling | #15 For filling 3kg to 30kg | 1 | |||||

| 4-6.Pressure model Screw | For the non-free flow product | 3 | |||||

| 4-7.Closure | For free flow product | 1 | |||||

| 4-8.Spinner | For small dosing weight | 2 | |||||

| 4-9.Siemens PLC & HMI | PLC:S7-1200

HMI:TP-700 |

1 | |||||

| 4-10.Extra Bag Clamp | For different size bag:W340-420mm | 1 | |||||

| 4-11.Pneumatic bag support device | V Shape | 1 | |||||

| EQUIPMENT INSTALLED AND START UP AT CUSTOMER’S PREMISES | |||||||

| PACKING & DELIVERY TO SITE (ex-works Pretoria) FAT-for buyers account | – | – | |||||

| PROJECT MANAGEMENT -INSTALLATION, COMMISSIONING, TRAINING | |||||||

| TOTAL including optional parts and installation | |||||||

Video Player

00:00

00:00

Video Player

00:00

00:00

Reviews

There are no reviews yet.