Description

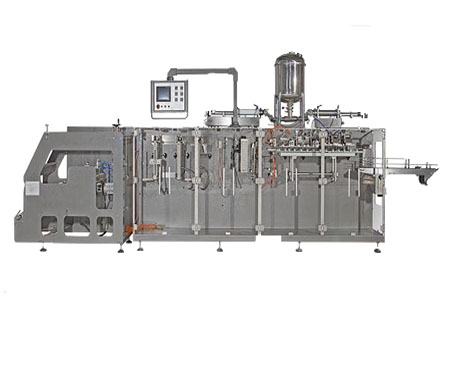

MODEL: Automatic Doy Bag forming and packaging machine for liquid and dry goods: HS-180 packaging main machine

Optional Printer

- Digit Cold Embosser

- Thermal Printer

- Inkjet Printer

- Laser Printer

Description of Packaging line

Equipment Requirements

Machine Standard Stand up Doy pouch

Dossing solution Piston filter

Sealing Checkers straight

Tear notch Diamond cut

Product contact parts 316 SS food grade

Machine frame 304 SS

Optional printer Digital Cold Embosser/ Thermal Printer/ Inkjet Printer/ Laser Printer

Pneumatic components Festo

HS-180cPackaging Machine with pump filter

HS-180 Automatic Packaging Line include

- One set of HS-180 packaging main machine

- Two sets of piston pump filler

- One set of 100L material storage tank

- One set of material level sensor

- NO pouch NO filling detector

- One set of outlet conveyor

- One set of inkjet printer

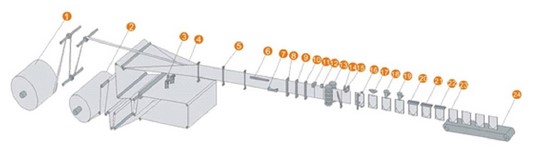

1. Zipper release (optional)

2. Film unwinding

3. Bottom hole punching

4. Pouch forming

5. Film guide

6. Horizontal zipper seal (optional)

7. Bottom seal

8. Vertical zipper seal (optional)

9. Vertical seal I

10. Vertical seal II

11. Tear notch

12. Photocell

13. Servo advance

14. Cutting

15. Pouch Catching

16. Pouch opening

17. Air flushing

18. filling I

19. Filling II

20. Pouch stretching

21. Top seal I

22. Top seal II

23. Finished product

24. Outlet

Equipment information

HS-180 packaging main machine standard configuration:

- A film reel auto-alignment shaft

- One set of bottom seal unit

- V-shape Standard Unit

- An independent bag former

- Three sets of horizontal sealing unit

- Two sets of vertical sealing unit

- Servo pouch puller

- Mechanical scissors

- Vacuum bag opening device

- Automatic material-level control system

- A photocell tracking control system

- A LCD touch control operation system

- A PLC control system

- A product outlet system

- An operation manual in English

Technical Parameters

Pouch Width 90-180mm

Pouch Length 110-260mm

Max Volume 1200ml

Speed 40-60 pouch/min

Accuracy <+-1.5%

Reel 500mm

Electricity Consumption 6.5Kw

Air Consumption 200NL/min

Weight 200kg

Size (L x B x W) 5550mm x 1100mm x 1400mm

Main Machine Electrical and Pneumatic Components

Main Components Vendor

PLC Mitsubishi Japan

Touch Screen Mitsubishi Japan

Inverter Mitsubishi Japan

Photocell Autonics Korea

Main Motor ABB Switzerland

Pneumatic Parts Festo Germany

Vacuum Generator SMC Japan

Temperature Controller FUJI Japan

Machine features

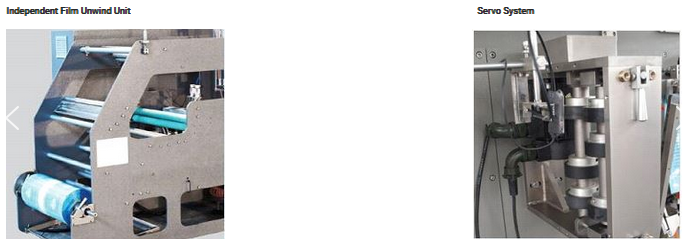

Independent Film Unwind unit

- ensures good control of film tensile force.

- More flexible for film roll width

- Improves doy-pack forming.

Servo System

- easy computerized specification change.

- Stable pouch advancement with less deviation

- Quick torque for pouch advancement, suitable for big volume