Description

RE: CANNED GROUND COFFEE FILLING LINE

Automated filling and sealing machine. Content: Coffee granules

The tin dimensions:

250g dimensions: 83mm x 135mm (diameter x height)

750g dimensions: 126mm x 172mm (diameter x height)

COMMERCIAL OFFER: – GROUND COFFEE CANNING LINE

| No. |

Description of each Machine |

Quantity |

Unit Price |

Amount |

Remark |

| 1 |

Can infeed rotary table |

1set |

|

|

Diameter 1000mm |

| 2 |

Automatic packing machine |

1set |

|

|

Single head with frame |

| 3 |

Screw loader |

1set |

|

|

|

| 4 |

Automatic vacuum can seamer |

2sets |

|

|

Can be injected nitrogen |

| 5 |

Can turning device |

1set |

|

|

Turn can upside down |

| 6 |

Laser inkjet printer |

1set |

|

|

|

| 7 |

Cover caping machine |

1set |

|

|

With cap drop function |

| 8 |

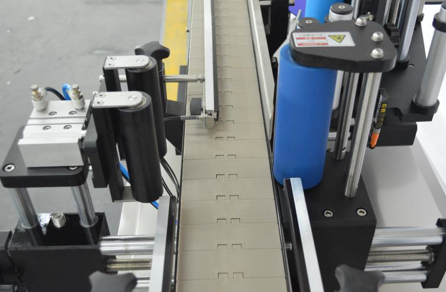

Round labeling machine |

1set |

|

|

One or two labels |

| 9 |

Can outfeed collection rotary table |

1set |

|

|

Diameter 1000mm |

| 10 |

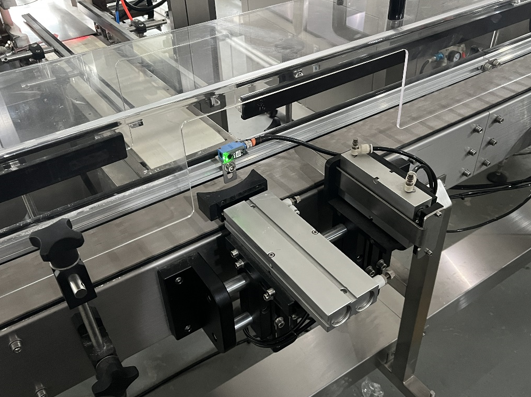

Conveyor |

18m |

|

|

With acrylic cover |

| 11 |

Dust collector |

1set |

|

|

|

| Total amount |

|

Delivered & installed & commissioned |

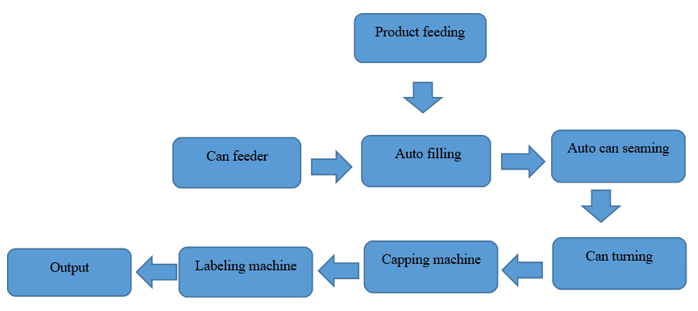

LINE FLOW

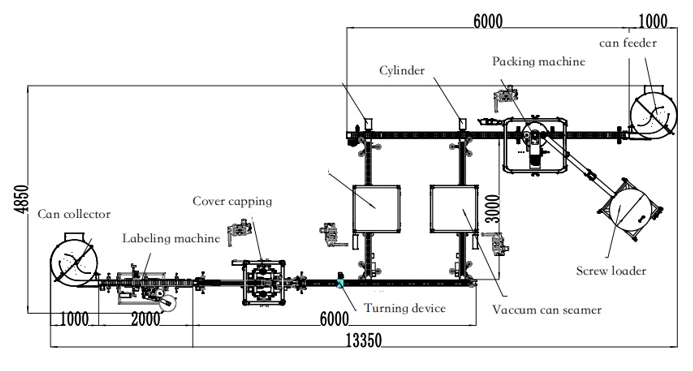

LINE LAYOUT

MAIN TECHNICAL PARAMETER

| No |

Name |

Machine Pic |

Technical specifications |

| 1 |

Bottle feeder |

|

Disk diameter:1000mm

Suitable to bottle: designed by bottle

Speed 2-6circle/m

Power: 0.37kw

Machine size: 1220*1000*1300mm

Machine weight: 100kg

|

| 2 |

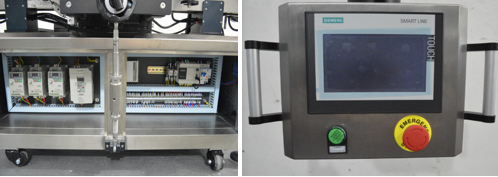

Powder packing machine |

|

| 2-1 |

Parameter |

No. of filling heads |

1 head |

| Filling Material |

Powder |

| Power supply |

380V 50HZ |

| Accuracy |

±1 % |

| Container capacity |

100-1000G |

| Filling speed |

15-30CPM |

| Air compressor |

0.6-0.8Mpa |

| Power |

3kw |

| Machine size |

2000*1200*2200mm |

| Machine weight |

300kg |

| 2-2 |

Material tank lifting rocker

|

|

Easy adjustment for different cans |

| 2-3 |

Vacuum loader |

|

Servo motor, high precise

|

| 2-4 |

Powder tank |

|

Visiable material checking |

| 2-5 |

Touch screen |

|

Siemens Touch screen |

| 2-6 |

Screw size |

|

|

| 3 |

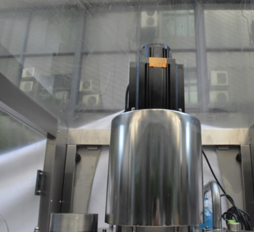

Vacuum can seamer |

|

|

| 3-1 |

Features |

This product is suitable for filling and sealing various round size cans

1. Complete vacuum pumping, nitrogen filling, and tank sealing work at the same workstation.

2. Tight sealing effectively protects product quality.

3. The air pressure and nitrogen content inside the tank can be adjusted according to customer requirements and specific circumstances to prevent tank suffocation and expansion.

4. Effective replacement of gas in the tank to extend the shelf life.

5. PLC and touch screen control.

6. Conveyor belt in and out of the tank.

7. All stainless-steel structure.

8. The tank body is cylindrical in shape.

9. Suitable for tin cans, composite paper, and other materials. |

| 3-2 |

Parameter |

Speed |

5-6can/m |

| Can size |

φ73─φ131mm/H100-190mm |

| Power supply |

3cph 208-415V 50/60Hz |

| Motor power |

4.5KW |

| Compressed air |

6kg/cm 0.125cbm/min |

| Nitrogen |

3.5M3/H/Set |

| Dimension |

3000*1100*1800mm |

| Machine weight |

400kg |

| 3-3 |

Inside photo |

|

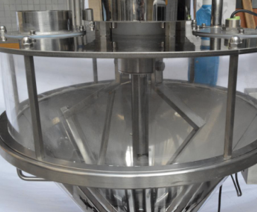

| 3-4 |

Vacuum part |

|

| 4 |

Cover capping machine |

|

| 4-1 |

Description |

1. This product is mainly suitable for sealing circular and square dust-proof rubber caps on various PET plastic, iron, aluminum, and paper cans. It has a simple structure and easy operation, and is used in industries such as food, medicine, tea, and chemical

2. The main body of this product is made of all stainless-steel material, with a simple and beautiful appearance.

3. The key parts adopt unique design, with high strength, low noise, and good sealing performance.

4. Fully automated production line design, which can be combined with filling systems, weighing filling systems, or labeling systems to form a streamlined production line. |

| 4-2 |

Parameter |

1. Capping speed: 30-50 cans/minute

2. Applicable tank height: 60-200mm

3. Applicable tank diameter: 50-120mm

4. Working temperature: 0-45 ℃, working humidity: 35-85%

5. Working power supply: AC220V 50/60Hz

6. Total power: 0.65KW

7. Heavy: 250KG (approximately)

8. Dimensions: 2000 * 1000 * 1800mm

9. Gas source pressure: 0.6-0.8MPa flow rate 0.15 cubic meters per minute |

| 5 |

Automatic round bottle labeling machine |

|

| 5-1 |

Labeling head |

|

| 5-2 |

Cabinet /touch screen |

|

| 6 |

Turning device |

|

Turning cans up down |

| 7 |

Laser printer |

|

Power: 120w

Max print lines: 3 lines

Print capacity about 3000 bottle per hour

Environment requirements: Temperature 5 ℃ _45 ℃

Humidity is less than 95%, no condensation

Weight: 18kg ·

Main Dimension: 345*285*540mm

Character size: 2-8.5mm

Power supply: 100-120/200-240V 50/60Hz |

| 7-1 |

Feature |

* High laser power

* The laser power is controlled by software, continuously adjustable

* Low processing costs, without any marking supplies

* Carving depth range to manipulate the tag

* Clear, not easy to wear and long life

* Can adapt to a variety of products

* Air-cooled: CO2 sealed laser head

* Wavelength of 10.6 micron

* Industrial grade controller

* Electronic control / scanning system

* LCD displayer

* English display large screen

* The friendly man-machine interface graphics, character free editing edit the date, time, minutes , second

* Automatic change serial number, batch and real-time clock information can be continuous with the month, day, and change when the large capacity storage space |

| 8 |

Plastic cover for conveyor |

|

Reviews

There are no reviews yet.