Description

Gable Top Carton Filling Machines

AUTOMATIC GABLE TOP CARTON FILLING LINE

Gable top filling line, filling volumes: 250ml, 500ml,750ml, 1000ml, automatic at 2500 – 3000 gables

per hour with optional capping system.

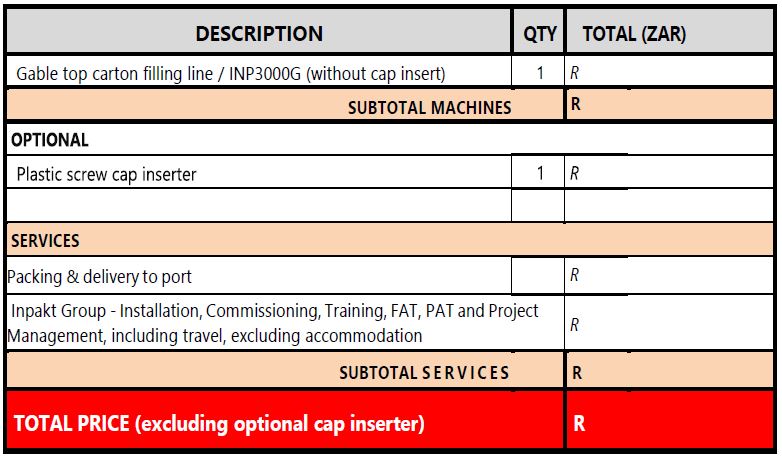

Price List

INP-3000G Type Gable-Top Carton Filling

INP-3000G type gable top carton filling machine is fully automatic with top level configuration. It is provided with different types to meet different customers’ need, according to the output, configuration, automatic degree, carton size, etc. B type machine: for filling type for wine, juice, tea drink, corn drink, soy milk, pure water, etc.

1) Work flow: Put carton into carton holder (manually) → Bottom preforming → Bottom heating and sealing → Ultrasonic capping (Optional)→ Filling → Top preforming → Top heating and sealing → Date printing → Finished product. The whole process is controlled by PLC, and only need:

Characteristic

− Very good appearance, applying environmental protection material.

− The machine is small, and doesn’t need large floor space. Carton magazine can hold 1000 carton pieces.

− The cartons don’t need to be washed, which saves a large amount in washing and sterilizing.

− Doesn’t require many workers to operate.

− Can apply hot filling, to increase the shelf life of the product for 3-12 months under normal temperature. That solved many enterprises’ problem of short shelf life.

− High-innovative filler, making it very desirable for many users worldwide

Technical parameter:

● Capacity: 250–1000ml / 1000ml-2000ml (can be filled by one machine)

● Output: 2500-3000 cartons/hour

● Packing material: cardboard carton / aluminium foil carton

(Carton bottom size 57*57mm, 70*70mm, 95*95mm, one size for one machine)

● Capping: With capping (Optional) cap size: φ26-φ36, one size for one machine

● Filling temperature: 2-50 degree centigrade

● Overall power: 25KW (three phases of electricity)

● Compressed air pressure: 1.0-1.4 Mpa, Flow rate: 1.4-2M3 /min, without oil, water and dust

● Cooling water: Flow volume:≥40L/ min Temperature:≤30℃

● Size: (L*W*H): 3.7m*1.6m*2.8m Net Weight: 3500kg

● Installation requirement: Any smooth floor, such as cement, floor tile, plastic flooring

● The machine is with carton lifting function to avoid foaming.

● The machine is made of food-grade 304 stainless

Features:

● PLC control, only need one person to run the machine.

● Apply touch screen which shows relevant information for operator to make the operation easy.

● Automatically record the working status which can be long-term saved.

● Automatic lubrication.

● Automatically failure alarm, diagnosing, and solution indicating.

● The filling capacity can be adjusted at will.

● The capping function is optional.

● Can be installed with remote debugging system, which can solve problems for long distance customers.

Major parts list:

1 The entire machine is made from 340 & 316 food-grade stainless steel, excluding the support

2 Heater: Swiss LEISTER

3 PLC: German Siemens

4 Extensive module: German Siemens

5 Pipeline solenoid valve: Taiwan AIRTAC

6 Pneumatic component: German FESTO

7 Touch screen: Weinview

8 Cylinder German: FESTO

9 Cylinder: Taiwan AIRTAC

10 Cylinder: Japanese SMC

11 Vacuum sucker: German FESTO

12 Air filter: Taiwan AIRTAC

13 Compressed air filter system: Taiwan AIRTAC

14 Fiber-optic sensor system: German FESTO

15 Oil way system: American BIJUR

16 Vacuum generator: German FESTO.