| 1.1 Air chilling machine

Technical parameters:

| Model |

SIB-20A |

| Cooling ability: |

52 kW |

| 44,720 kcal/hr |

| Compressor(output power): |

16.12 kW |

| 20 HP |

| Refrigerate agent: |

Weight: |

18 Kg |

| Controlling method: |

thermal expansion valve control |

| Type: |

R22 |

| Evaporator: |

Shell type |

| Condenser: |

Type: |

Finned condenser |

| Fan power: |

0.45 kW |

| Water tank volume: |

80L |

| Water pump: |

Power: |

1.1 kW |

| Water flow: |

80/100/89 L/min |

| Working pressure: |

2.0/2.6/3.5 kgf/cm² |

| Total power: |

7.71 kW |

| Actual power consumption: |

40-70% |

| Pipe fitting: |

Water inlet diameter: |

1.5 inches |

| Water outlet diameter: |

1.5 inches |

| Water tank discharging hole diameter: |

1.5 inch |

| Water tank overflow hole diameter: |

1.5 inch |

| Protection devices: |

Compressor: |

Overload relay |

| Pump: |

Overload relay |

| Chilling circuit: |

High/low voltage switch / anti-frost switch |

| Water loop: |

Bypass valve |

| Power supply: |

380V 50 Hz |

Component list:

| Items |

Supplier, Origin |

| Contactor |

Schneider, France |

| Thermal relay |

Schneider, France |

| Thermal temperature table |

Schneider, France |

2. High pressure air compressor

Technical parameters:

| Model |

2-52SH-13.0/40 |

| Capacity: |

13.0 Nm³/min |

| Rotating speed: |

690 r/min |

| Power: |

105 kW, IP44, Insulation Class B |

| Rated pressure: |

3.0 Mpa |

| Stroke: |

92 mm |

| Dimension: |

2200*1950*1650 mm |

| Weight: |

3000 Kg |

| Delivery connector: |

11/2”NPT |

Electric Components

| Items |

Supplier, Origin |

| Motor |

Siemens, Germany |

| High pressure valve train |

HOERBIGER, Austria |

| Waste discharging system |

Jorc, Netherland |

| Output pressure switch |

Danfoss, Denmark |

| Contactor |

Schneider, France |

| Breaker |

| Thermo relay |

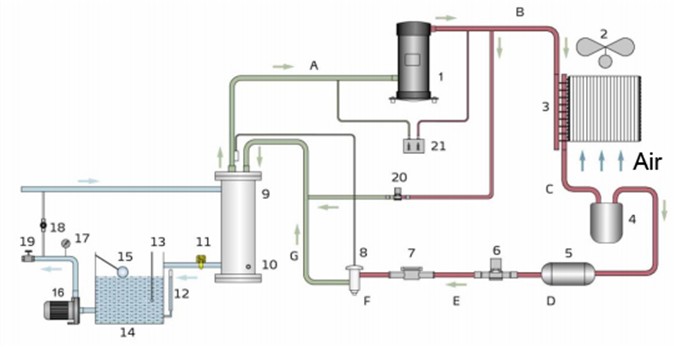

2.1 Compressed air-cooling drying filtering system

Technical parameters:

| Model |

NTLN |

| Capacity: |

13.0 Nm³/min |

| Working pressure: |

4.0 Mpa |

| Water filtering capability: |

99% |

| Cooling ability: |

1.5 HP |

| Dew point: |

2-10°C |

| Stroke: |

146 mm |

| Cooling agent: |

R22 |

| Initial filter: |

Oil ≤ 5mg/m³, Granule dia. ≤ 3um |

| First stage precision filter: |

13.0 m³, 4.0 Mpa,

Oil ≤ 1 ppm

Granule dia. ≤ 0.3 um |

| Second stage precision filter: |

13.0 m³, 4.0 Mpa,

Oil ≤ 0.01 ppm

Granule dia. ≤ 0.01um |

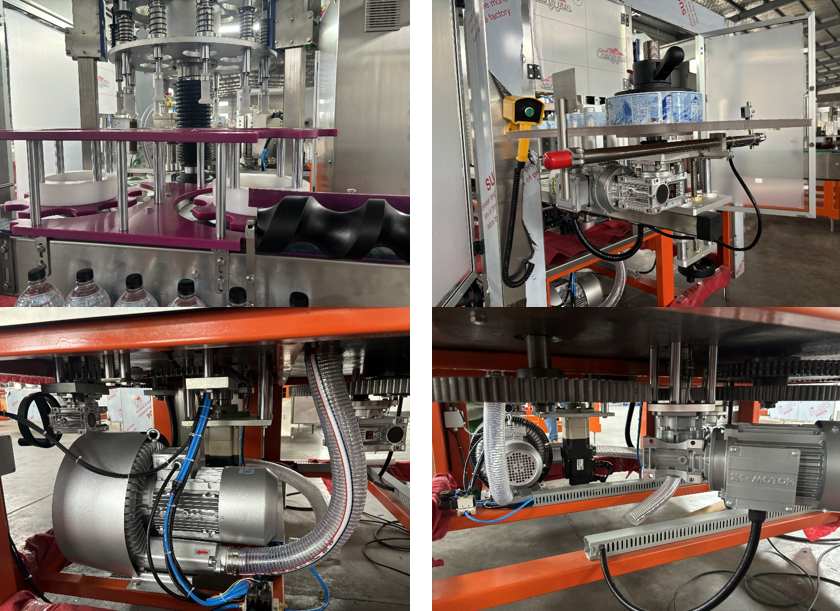

FILLING & PACKAGING EQUIPMENT

1. OPP labeling machine

Machine composition:

A: Labeling station

Schneider Micro inertia servo motor

Schneider servo amplifier

Schneider Programmable Controller (PLC)

Schneider human machine interface (Chinese and English bilingual operation interface)

German SICK or American LION label sensor

German SICK product detection photoelectric switch

B: Mechanical part

Spindle mechanism: NORD AC motor

Schneider frequency converter speed regulation

Gear transmission system

Cam pressing bottle system

Presser transmission system

Bottle holding base transmission system

Height regulation system

Bottle feeding mechanism: special non-damage bottle star wheel, connected with the main turntable gear, adjust the spacing

Special inlet star wheel, connected with main turntable gear, main turntable transition mechanism

Chain width 82.6 mm

Bottle discharging star wheel: connected with the main turntable gear, the bottle is smoothly fed into the conveyor line

Label pressing mechanism: sponge spring steel plate combination, Teflon patch

Bottle guiding mechanism: double coordinate wear-resistant casting nylon

C. Equipment safety protection

Safety protection: Close the protective door when the equipment is running to prevent injury to the operator

Missing alarm: set the label will be used when the alarm prompts to remind the operator to prepare to replace the label

Bottle shortage alarm: When bottle shortage is detected, the equipment will alarm; when bottles detected, it will automatically resume production, which is convenient for in-line production.

The mechanical structure of the whole machine adopts the reinforced rigid design, which is simple and stable.

Technical parameters:

| Model: |

TB250R12 |

| Output: |

22000 Bottles per hour |

| Labeling heads: |

12 |

| Main motor power: |

1.5 kW |

| Total power: |

10 kW |

| Compressed air consumption: |

0.2m3/min |

| Bottle diameter: |

28-125 mm |

| Sleeve label length: |

30-250 mm |

| Thickness: |

0.035mm |

| Label material: |

OPP |

| Dimension: |

3240*2190*2400 mm |

| Weight: |

1950 Kg |

Component list:

| Items |

Supplier, Origin |

| PLC |

Schneider, France |

| HMI |

Schneider, France |

| Main motor servo system |

Schneider, France |

| Label station servo system |

Schneider, France |

| Label station VFD |

Schneider, France |

| Label feeding servo system |

Schneider, France |

| Photoelectric sensor |

SICK, Germany |

| Encoder |

SICK, Germany |

| Label sensor |

Panasonic, Japan |

| Bottle absence sensor |

SICK, Germany |

| Bottle jam sensor |

Panasonic, Japan |

| Aproximity switch |

Telemecanique(Schneider, France) |

| Aproximity switch |

Autonics, South Korea |

| Label absence label |

Panasonic, Japan |

| Conveyor motor VFD |

Schneider, France |

| Bottle holder VFD |

Schneider, France |

| Handle wheel

(For manual operation) |

Schneider, France |

| Isolating switch |

Schneider, France |

| Temperature Controller |

Autonics, South Korea |

| solid state relay |

HRO, South Korea |

| Relay base |

Schneider, France |

| Intermediate relay |

Schneider, France |

| Breaker |

Schneider, France |

| Breaker |

Schneider, France |

| Breaker |

Schneider, France |

| AC contactor |

Schneider, France |

| Breaker |

Schneider, France |

| Isolation transformer |

CHNT, China |

| Switching power supply |

Schneider, France |

| Fuse |

CHNT, China |

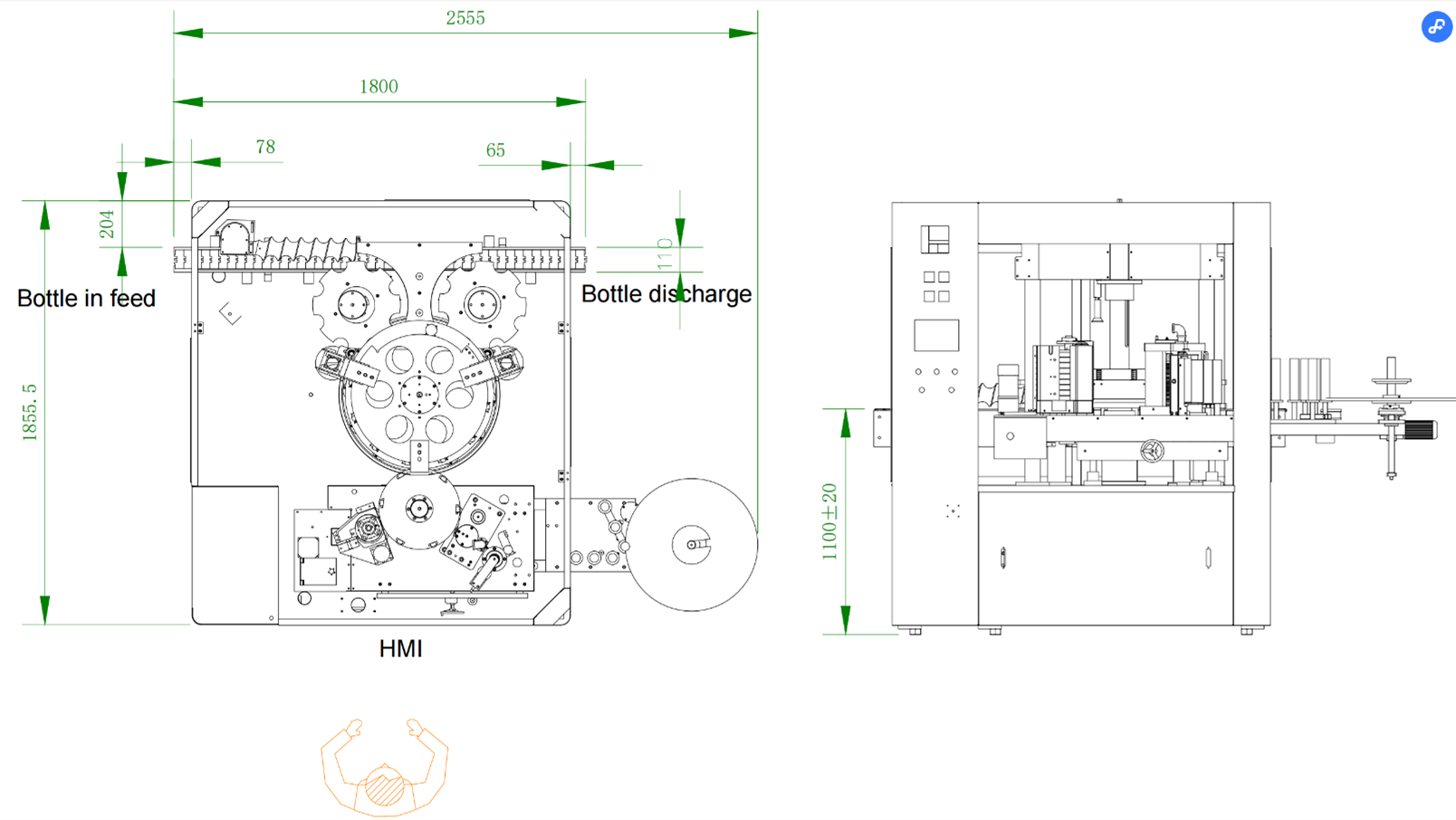

2. Filling-capping Duo-block (weigh fill)

Technical parameters:

| Model: |

ZPGF40-8 (PET bottle) |

| Capacity: |

8000 B/H (5000ml) |

| Bottle height: |

120-360 mm |

| Bottle diameter: |

50-200 mm |

| Bottle mouth diameter: |

38-46 mm |

| Bottle type: |

PET bottle |

| Cap type: |

Flat cap |

| Filling heads: |

40 |

| Filling temperature: |

Room temperature |

| Filling valve material: |

SUS316 |

| Product reservoir tank: |

SUS304 |

| Capping heads: |

8 |

| Capping torque: |

0.6-2.8 Nm (adjustable) |

| Main motor power: |

5.5 kW AC 400V 50Hz IP55 |

| Installation power: |

10 kW |

| Power supply: |

415V, 50HZ |

| Consumption of compressed air: |

0.8 m³/min (0.6MPa/H) |

| Consumption of aseptic water: |

3.5 m³/h (0.2-0.25Mpa) |

| Dimension: |

5300*3800*2600 mm |

| Weight: |

15500 Kg |

Component list:

| Items |

Supplier, Origin |

| PLC |

Siemens, Germany |

| Touch screen |

| VFD |

Danfoss, Denmark |

| Contactor |

Siemens, Germany |

| Thermal relay |

| Switches |

| Micro relay |

| Photoelectric electric sensor |

Banner, USA |

| Pneumatic cylinder |

SMC, Japan |

| Electromagnetic valve |

| Air filter, pressure reducing valve, oil mister |

| pressure adjusting valve |

| Main Motor |

ABB, Switzerland |

A. Filling part

B. Capping Station

Features:

• Caps will be unscrambled in the silo, the amount is monitored.

• Capping torque can be adjusted accordingly

• A flip-over adjuster installed on the slide to avoid up-side-down caps.

• Two photoelectric sensors installed on the slide to alarm the cap-absence.

• The capper is able to adjust the height to match the different-height bottles.(have maximum and minimum height protection)

D. Cap hopper (for HDPE cap)

Technical parameters:

| Model: |

TSG-1A |

| Cap type: |

Flat cap / sports cap |

| Material: |

SUS 304 |

| Conveying capacity: |

20000 caps/h |

| Power: |

0.37 kW |

| Manufacturer: |

INPAKT |

3. Laser printer

Technical parameters:

| Model: |

JGJ |

| Laser printing head: |

1 |

| Max power: |

10 W |

| Cooling method: |

fan |

| Maximum printing speed: |

500 characters/min |

| Maximum line speed: |

60 m / min |

| Environmental protection: |

IP20 |

| Life service of the laser source: |

Up to 30,000 hours |

| Beam output: |

Controlled beam |

| Laser wavelength: |

10.6 um |

| Focus length: |

100-200mm |

| Operation: |

HMI |

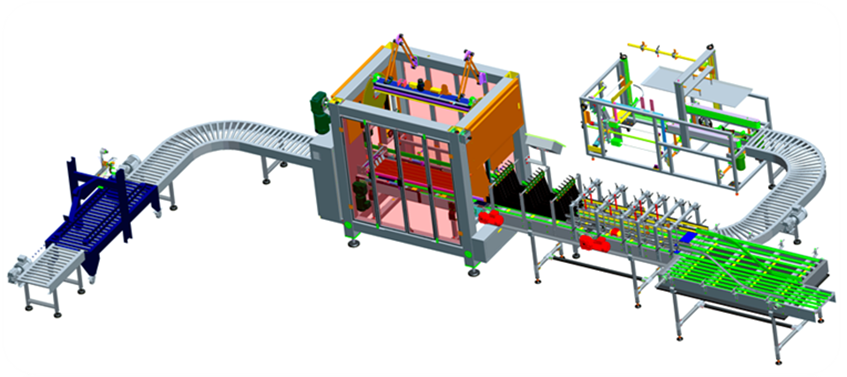

4. Cartoning system

4.1 Automatic Carton erector

Technical parameter:

| Model: |

KX-18 |

| Carton size: |

L200-400* W150-350*H100-350 |

| Capacity: |

18 p/h |

| Carton store capacity: |

100 pcs (1000mm) |

| Dimension: |

2400*2050*1450mm |

| Power supply: |

220V,50Hz |

| Air pressure: |

6 Kg/ cm2 |

| Air consumption: |

450NL/min |

| Size of the tape: |

48, 60, 75mm for option |

| Weight: |

550kg |

4.2 Automatic carton packing machine

Technical parameter:

| Model: |

ZX-20K |

| Capacity: |

cartons short edge into the box, 4 boxes once, and standard speed:

18cases/min |

| Packing layer: |

One layer |

| Power supply: |

380V; 50Hz |

| Power: |

5.5 kW |

| Dimension: |

3340*1680*2800mm |

| Air pressure: |

6-8 bar |

| Air consumption: |

350 NL/min |

| Weight: |

2500 Kg |

4.3 Automatic carton sealing machine

Technical parameter:

| Model: |

FX-25 |

| Packing speed: |

18 cartons/min |

| Tape width: |

36~70mm |

| Max carton size: |

L600*W500*H500mm |

| Minimum carton size: |

L200* W150*H150mm |

| Power: |

400W |

| Size: |

1770*850*1500mm |

| Weight: |

250kg |

Component list:

| Item |

Brand, Origin |

| PLC |

Siemens S 7 series with Profinet

(CPU 1200 and above) |

| Touch screen |

Siemens TP 900 |

| VFD |

Danfoss FC 302 |

| Linear guide rail |

IGUS, Germany |

| Pneumatic components |

FESTO, Germany |

| Low voltage electric components |

Schneider, France |

| photoelectric sensor |

SICK, Germany |

5. Belt conveyor & Buffering system

Technical parameters:

| Motor power: |

0.37 kW / 6m |

| Width of the conveyor: |

110 mm |

| Height: |

1050 mm |

| Thickness of the steel plate: |

2 mm(SUS304) |

| Bottle volume: |

200-3000 ml |

| Bottle Diameter: |

50-100 mm |

|

Reviews

There are no reviews yet.