Description

Cosmetic Creams Packaging Lines

| SUB: COSMETIC CREAM PROCESSING, FILLING & PACKAGING LINE

Scope: Water treatment RO system, Cream Processing, bottle and jar filling and capping, plastic tube filling and sealing, singles item cartoning. |

COMMERCIAL OFFER :-

COSMETIC CREAM PROCESSING, FILLING & PACKAGING LINE

1) Water treatment Reverse Osmosis 500LPH

Grouping 1 – Raw Water Pump to R.O output consists of the following items.

Quote 1 price for the entire block…* Raw water tank from Municipal Jojo 5000L

1.) Supply pump to R.O 220V 0.75 Kw Stainless – R4325

2.) R.O Pre-filtration 2000 lph Sediment & Carbon with media and Digital backwash heads R21 067

3.) Antiscalent system for R.O (used instead of a softener ) 200 Liter tank with 7 bar dosing pump @ 5lph

4.) Industrial High Recovery system >75% 500 lph

5.) product Tank stainless you must Supply.

Grouping 2- CIP tank & Pump,

Grouping 3- Cold Plasma UV Germicidal System for product water from R.O tank, 5 Micron 20″ Housing & Filter (policeman filter in case of sediments in the R.O product water tank)

2 x membranes for the R.O.

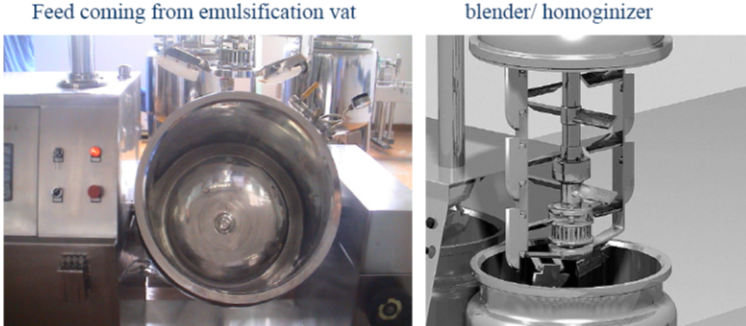

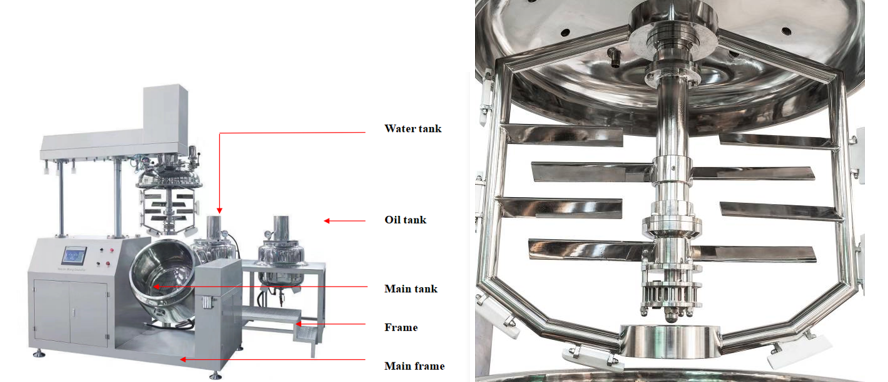

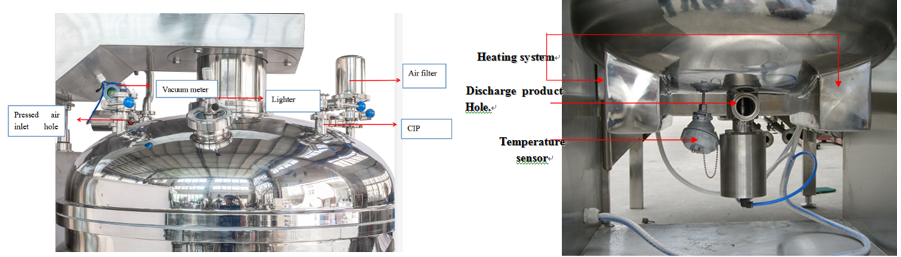

2) 200L vacuum mixing emulsifier (homogenizer)

I. Application

This unit can be used for production of ointments and creams in cosmetic and pharmaceutical factories, especially for the preparation and emulsification of ground substance with high viscosity and high content of solids.

This unit applies upper coaxial triple type mixer and hydraulic lifting mode to open the cover. The speed of rapid homogenizing mixer is 0-3500 rpm (frequency control); the speed of slow-speed scraping mixer is 0-70 rpm (frequency control); the homogenizing head applies high cutting eddy current type emulsifying mixer. The slow-speed scraping mixer automatically abuts closely to the bottom and wall of boiler. By applying vacuum sucking, this unit can suck in powder material by using vacuum to avoid powder flying upward. The whole process is performed under the vacuum condition in order to keep from the production of air bubble after the material is mixed at high speed and up to hygienic asepsis requirement. This system is equipped with CIP cleaning equipment. The parts of container, which contact the material, are made of SUS316L stainless steel and inner surface mirror polish is up to 300MESH (sanitary level). In order to ensure stability of control part, the electric control parts apply the products from German Siemens, the press key from Japan FUJI Corp., frequency converter from Panasonic Electric Works, and vacuum pump from Siemens Corp.

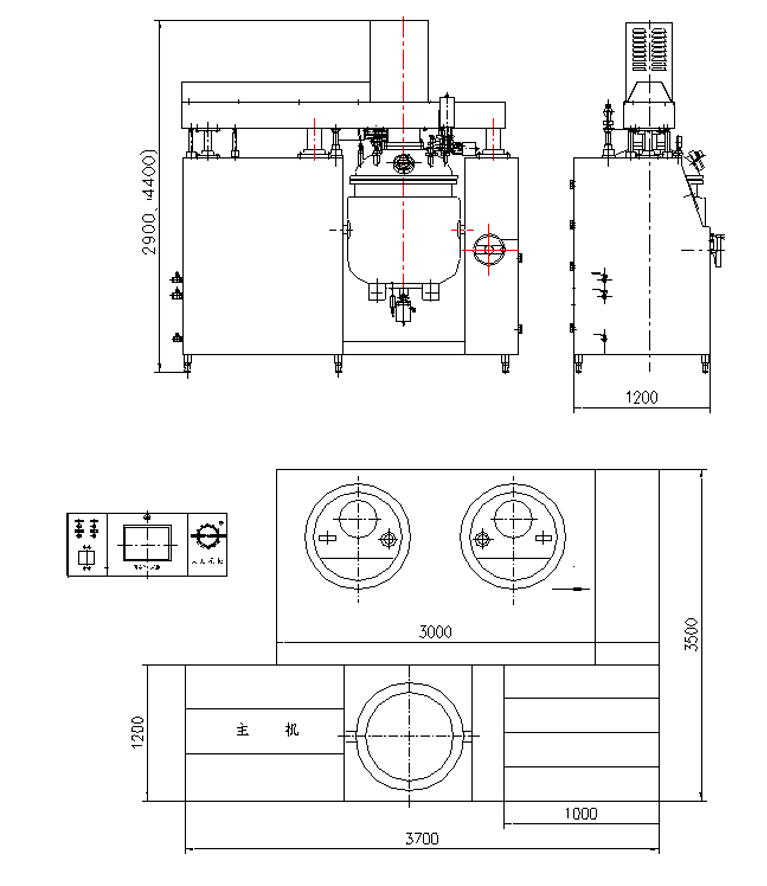

| Technical parameters: | |||||||||

| Model | Volume | Emulsify motor | Mixer of oil water pot | Length | width | height | Max height | ||

| VM-200 | 200L | 4KW | 0-3500rpm/min | 1.5kw | 0-60r/m | 2850 | 2200 | 2200 | 3100 |

LOW-SPEED MIXING SYSTEM

- Two reversed low-speed mixing systems, composed of a hanging bracket full of scrapers as well as impeller.

- The full automatic movable scraper’s surface is made of PTFE, only working under the condition with material. It’s easy for disassembly and cleaning.

- Dynamic balancing coaxial shaft

- Outer hanging brackets and inner impellers are made of stainless steel SUS316L.

- The timing is controlled by PLC to facilitate the setting of working time. The mixer will not work if the time is not set.

- The speed of the equipped reduction motor can be controlled directly by transducer to 10-40 rpm.

The low-speed mixing system produces two independent countercurrent flows inside the material.

1) One vertical fluid along the center can force material to fluid to the bottom of container. Its function is to convey the material to the bottom of homogenizing-turbine rapidly.

2) Another circle flow forces the material encircle the inner wall of the mixing container to facilitate the material to make heat-exchange during heating or cooling stage, which can prevent the material from being damaged due to overheat or overcooling.

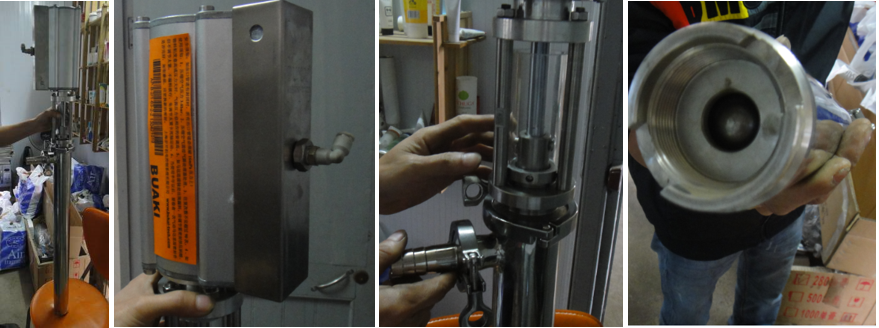

HIGH SPEED HOMOGENIZING MIXING SYSTEM

- High-speed homogenizing-mixing activity is accomplished by one turbine installed on the center bottom of tank.

- Turbine is composed of dentate stator and rotor with impeller.

- Turbine is made of stainless steel SUS304 or SUS316L, rotating parts pass the dynamic balancing coaxial shaft.

- The timing is controlled by PLC to facilitate the setting of working time. The mixer will not work if the time is not set.

- Adjust speed by frequency control: 1150-3500 rpm

- This kind of structure i.e. executing on the turbine not from the bottom can assure high cleanness of the process project. The reasons are as follows:

- The material will not be polluted without the influence of motor flange connection.

- Turbine is made easy for cleaning, maintenance, assembly and disassembly.

- The bottom of tank is completely smooth without connection and is easy to clean.

- Assemble a valve on the center bottom of the tank for discharge.

- The mixing and homogenizing motors are installed on the top of the tank, which is far from the processing area.

- Strictly ensure the safety of the operators.

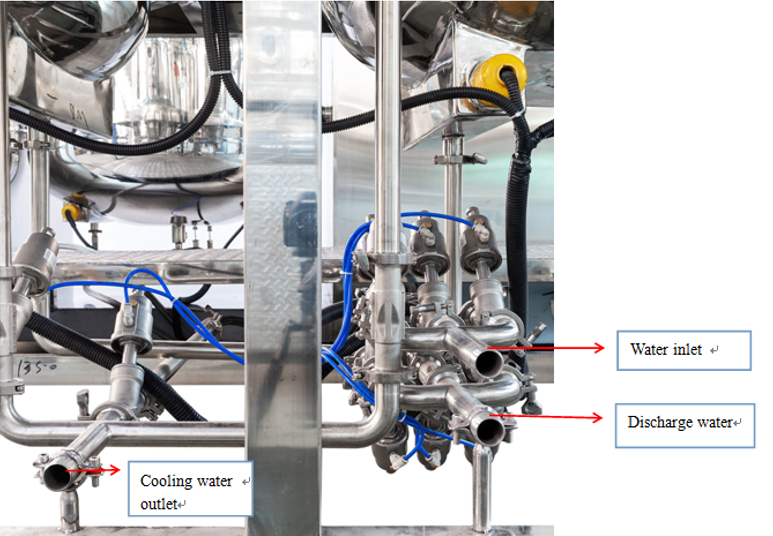

HEATING/COOLING SYSTEM

- Heated by the steam in the double jackets.

- The temperature of material in the container may be controlled through temperature sensor signal from the PLC.

- Temperature control is composed of PLC temperature module and temperature sensor installed at the bottom of the tank. Actual temperature of material may be read

- Cooling is directly accomplished by the external cold water through the jacket.

VACUUM SYSTEM

- Liquid ring vacuum pump is equipped with solenoid control valve at the water entrance.

- Vacuum gauge indicates the vacuum in the

- The vacuity may be set by using the vacuum sensor signal through PLC so as to control ON /OFF of vacuum pump.

- Vacuum safety switch is designed to keep the upper cover from opening at the state of vacuum.

- Airtightness of upper cover is ensured by the silicon filling material on the flange.

- Theoretically, max. vacuity is 730 mm/Hg at 20℃. In order to get optimal emulsifying result, air mustn’t enter into the material. For the process under vacuum condition, you’re allowed to add liquid or powder to the container directly.

UPPER COVER LIFTING SYSTEM

- The lifting of upper cover is fulfilled by a series of hydraulic devices. The device is fitted with a safe limit system, which can keep the upper cover stopping at any expected position.

TILTING SYSTEM OF CONTAINER

- Tilting system of container used for discharge is accomplished by a series of mechanical devices and stops at any angle.

FEEDING SYSTEM

- Directly add the material to the tank after opening the cover.

- Under the vacuum condition, the material will be absorbed into the tank by the suction valve through the strainer. Under the vacuum condition, the additive (powder) will directly enter the turbine through the hoper for excipient and additive mounted on the upper cover or the valve at the center bottom of tank so as to shorten the dispersing time

DISCHARGING SYSTEM

- Discharge the material from the container (at about 95°).

- Positive-pressure discharging through compressed air is available.

PROCESS CONTROL

- Observation window is equipped with wind board and lamp with good inner visibility.

SAFETY SYSTEM

- Safety lock can prevent the upper cover from opening under the vacuum condition.

- If the upper cover is not completely aligned with the container without enough tightness, stop using it.

- If the upper cover is not lifted entirely, stop using tilting function.

- When the upper cover is open, stop using the mixing and homogenizing motors and vacuum pump.

- Limit micro switch automatically executes the ON/OFF of the upper cover.

- Limit micro switch automatically executes the tilting/putting straight of the upper cover.

- Control device will prevent the water in the empty chamber from reaching the boiling point.

- The double-key system for sealing the upper cover accords with prevalent EC safety standard.

Note: different parameters can be altered to the request of users to reach optimal performance.

Technical Parameter and Components:

Container: connected with vertical and protruding flange with leading edge, equipped with double jackets.

Steam heating: Cool the double jackets with indirect system by water

Service modes of container: atmosphere/vacuum

Base of container: welded and high-grade mirror polish.

III. Vacuum system

Vacuum pump with Siemens 2BV2-061, bleeding air flow 52 M³/h and motor power 1.1 KW, vacuum pump.

- Hydraulic system

Including magnet valve, overflow valve, oil box and pressure- keeping valve.

- Electric control system

Electric elements made by Siemens Corp., transducer made by Panasonic company, keys made by FUJI company, the meter and sensor are high grade products at home.

- The touch screen control with PLC is adopted Siemens S7-200 series.

- Touch screen made by DIGITAL Corp., Japan with 10.4 inch.

- The touch screen shall be adjusted to display the functions including rate of mixing, temperature of each tank, set temperature to upper and lower limits, control automatic valve, set emulsification and slow-speed mixing time, control hydraulic system to ascending and descending, etc.

IV. Working platform:

It is made of complete stainless steel, with stainless steel figured plate on the surface.

Layout

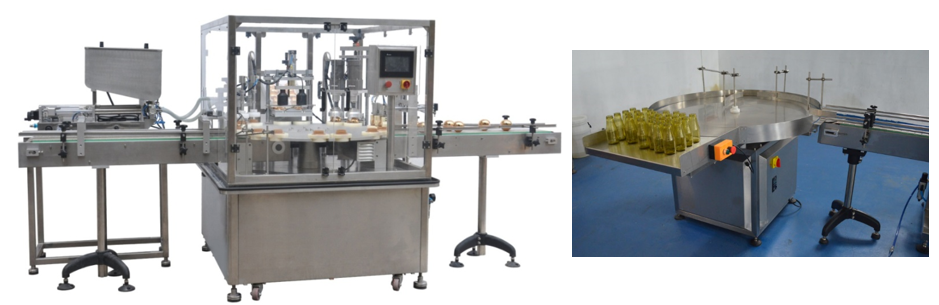

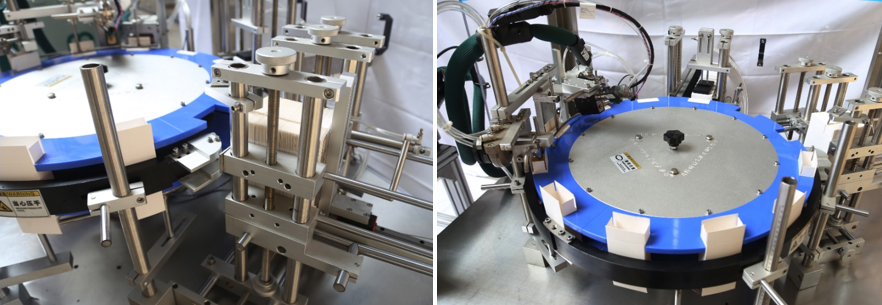

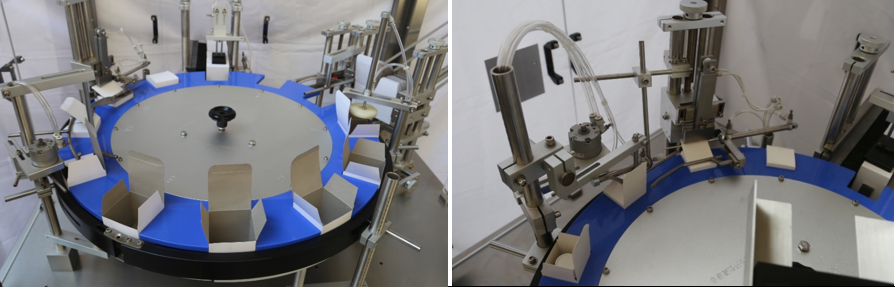

3) Automatic Rotary bottle filling & capping machine

Application:

- Designed in accordance with the sample bottle including food, medicine, cosmetics, petrochemicals and daily articles;

Features:

HMI operation, PLC control;

All material contact parts are made of 316L stainless steel, and surface is made of 304 stainless steel, fully up to related food sanitation standard;

High-precision filling control, with bubble-proof and drip-proofing;

Rotary disk structure, excellent design, compact structure;

This equipment is integrated multi-station packaging equipment, and the stations include: filling (one head or double-heads), capping) and cap-pressing, cap-screwing.

| Filling volume | Filling precision | Output | Power supply |

| 10-120ml

25-250ml;50-500ml |

±1% | 10-15bottle/min(one head)

20-30 bottles/min(two heads) (depending on material type and bottle size) |

AC220/380V 50/60Hz |

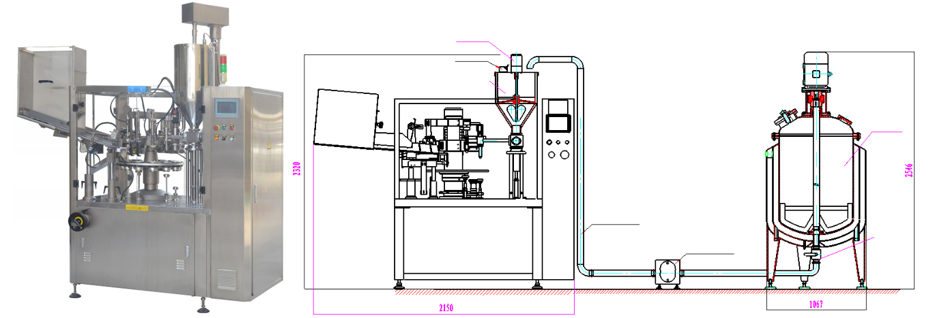

4) Automatic tube filling & sealing machine

Characteristics:

- PLC control system operated,

- Compact design and auto tube feed. Driving part fully-closed.

- Tube washing and feeding marking identification, filling, folding, sealing, code printing and finished product output all conducted by a fully auto control system.

- Auto picketage by photoelectric inductance.

- Intelligent temp. control system

- Quantity memorizing and quantitative shutdown device.

- The part contacting materials is made of 316L stainless steel, clean, sanitary and conforming to GMP for medicine manufacture.

- Overload protection provided.

———

-Electrical consumption: main motor(2.2kw);

*Jacket barrel heating(2kw); * Jacket barrel blending(0.18kw) (* options)

-Compressed air consumption: 1.1³ /min @0.5-0.6Mpa

Specifications

| Tube Application | Plastic, laminated Aluminium |

| Tube range | D10-50mm; L50-240mm |

| Packing speed | Max 80 Tubes/Min. |

| Filling volume | 5-350ml |

| Filling Accuracy | 0.5% |

| Hopper volume | 40L |

| Electrical supply | 380V/3 phase/50Hz |

| Size | L2500-W1200- H2400mm |

| Weight | 1200Kg |

6) Vertical carton packing Machine

Automatic carto folding machine (carton folding- filling-packing). It is specially design to automatic fold multi size carton, suitable for various size of carton. The machine is a vertical type with multiple function and require a short-time to change mould. The product is manually drop into carton. Suitable for round bottle, medicine, food-stuff, cosmetic, tube etc

7) Electric Shrink Sleeve Label Heat Tunnel 1000MPA

FEATURES

Frame: Heavy duty mild steel

Finish: Powder coated (Goose grey and red structure)

Heat Chamber Dimension

Length: 2000mm

Width: 200mm

Height: 300mm

Speed: Up to 100 BPM

PLC: Delta DVP 14

VSD: Yaskawa

Conveyor: High Heat Modular

Switch Gear: Lovaio

MCB: Hager

Heating Capacity: 12 Kw

Geared Motors: Motovario Italy

Electrical Requirements: 38OVolts 3 phase neutral earth. (25 amps per phase)

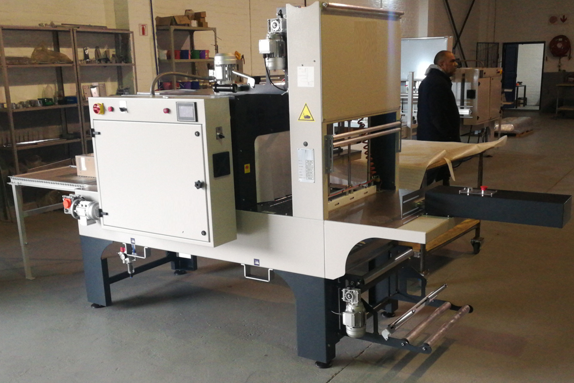

9) Shrink wrapper – For shrink wrapping into multipacks

Frame-Heavy duty mild steal

Finish-Powder coated

Sealing System- Impulse heat-sealing system, air operated to ensure smooth

operation and constant sealing pressure.

Hot Box-900mm heat chamber

PLC-Delta

Conveyor-Galvanized wire mesh

Switch Gear Lovato

Sensors-Omron

MCB-Hager

Heating Capacity-18kw

Control Station LCD display keypad with fault on screen and audio beep on any fault

Machine Dimensions L2900 / W1500 / H2000mm

Offer to supply-Manually infeed combination sleeve sealer and shrink tunnel with opening dimensions of

650 wide x 400mm high our Model 58SM4

Electrical requirement-380 Volts 3 Phase Neutral and Earth. (45 amps per phase).

Compressor requirement-Cleon source of dry air at 500 KPA (100 It. free air per minute).

Reviews

There are no reviews yet.