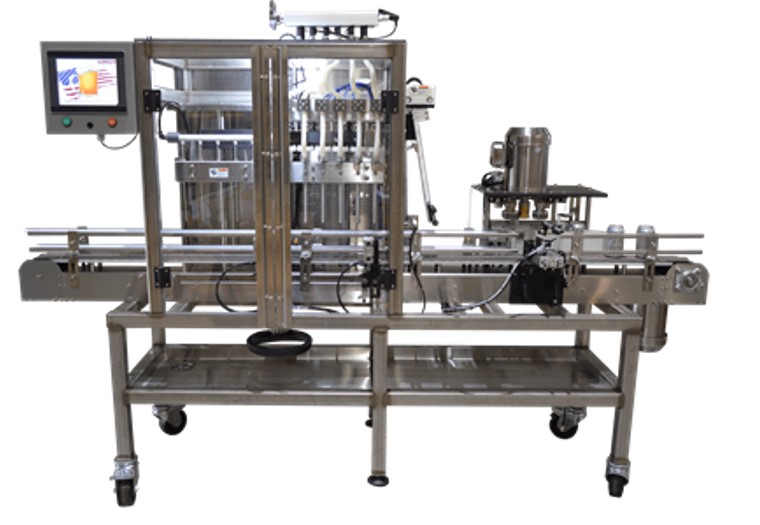

Micro-Brewery Can Filler

The INPF-5 Can Filler and Seamer does all the hard work for you. Completely automatic, the cans are shuttled over and placed under the filling nozzles. First, doused with CO2 to remove any atmosphere prior to filling with your product.

Using genuine pinch valves, the product flow is controlled to ensure no waste. Flow meters are placed on each head for fine adjustments made on the fill height to make sure it suits your operation.

Once filling is complete, a drip of CO2 is applied to remove any atmosphere from the open can. The lid is then placed on the top and then sealed. Once finished, the sealed cans exit onto an accumulation table for packaging.

Technical Data Micro-Brewery Can Filler

- Nominal Capacity: (340ml cans/min) up to 30

- Conveyor Height: 1719 mm

- Conveyor Length: 2642 mm

- Machine Width: 788 mm

- Power Requirements: 120-volt Single Phase, 60 Hz, 6 amps

- Compressed Air: 90-100 PSI at 10 cfm

Video

Brochure

Coming soon.